Phone : +91-9827113763 | +91-7587733050

Balancing

Balance quality grading

Fan Balancing, Impeller Balancing, Rotor Balaning in Delhi India. The relationship of permissible eccentricity a with speed n for a number of balance quality grades, G1 , G2.5, etc. specified in ISO 1940. The international committee responsible for this specification has tentatively (1973) proposed quality classifications for particular products. It will be seen that G 6.3 is the grade considered appropriate for fan impellers.

Close tolerance on the shaft-hub fit are essential, and must not be spoiled by careless fitting. Dynamic unbalance will be produced by a small run-out such as might result from forcing the impeller on against a bruised shaft or shoulder.

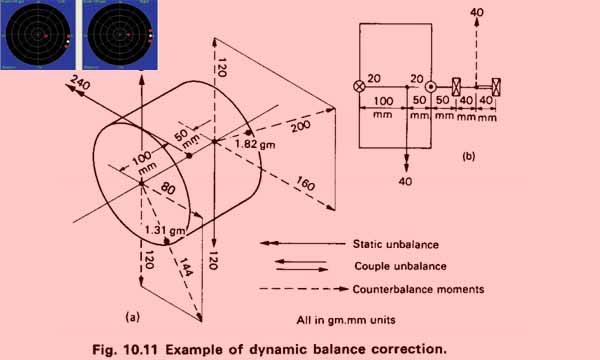

Impeller with a breadth exceeding some 20% of the diameter are likly to require dynamic balancing.this involves driving the rotor in the bearings of a balancing machine which are soft mounted in the horizontal direction. The resulting bearing vibration are picked-up, analysed and displayed to show the positon and value of the counterweight to be attached in two selected correcting planes.

Product Description

Turning Point Engineers have all Machinery facilities including a Dynamic Balancing Services with capacity up to 15 tones.

Typical rotating elements Balancing likely to be acceptable within grade:

- Fan Impellers

- Blower Impellers

- Pump Impellers

- Electric Rotors, Armatures

- Fly Wheel

- Turbines

- Balancing of Rolls

- Pulleys Balancing

- General Machinery

- Crankshaft Drives

- Car Wheels

- Brake Drum

| It will be Balanced by quality grades A B C and D | G1, G2.5, G6.3 and G16 + respectively for Class I machines and components. |

| Capacity | upto 15 tones |